|

Thread Number: 759

725 Design Oddities |

[Down to Last] |  |

| Post# 7717 , Reply# 2 1/7/2007 at 20:54 (6,315 days old) by vintagehoover () | ||

|

No, I've never seen one of those - I'd love to, though, they sound interesting! Of course, we didn't get any headlamps over here until the 450/800/925 range came along! | ||

| Post# 7731 , Reply# 6 1/7/2007 at 22:07 (6,315 days old) by vintagehoover () | ||

|

Ah - just occurred to me: once the 750 came along, there was a lower speed for delicate rugs, so the the holes wouldn't be needed (if that is indeed what they were for!). | ||

| Post# 7742 , Reply# 9 1/7/2007 at 22:47 (6,315 days old) by vintagehoover () | ||

|

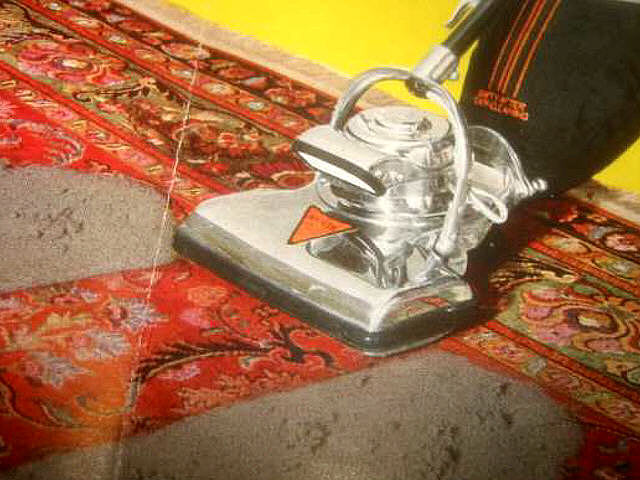

This being the 750's one of course...if you compare, the one in the photo above does look much smaller...

| ||

| Post# 7744 , Reply# 10 1/7/2007 at 22:54 (6,315 days old) by charles~richard () | ||

|

I think that is it, but it's kinda hard to tell in the photo. Once I get my Mac back up I'll be able to post photos of it. | ||

Comes to the Rescue!

Comes to the Rescue!