|

Thread Number: 3302

Paging Dr Lux Filter Queen on the operating table |

[Down to Last] |  |

| Post# 37083 , Reply# 1 4/3/2008 at 16:35 (5,856 days old) by kirbysthebest (Midwest) | ||

|

OHHH Doctor It was so lucky you were there to do emergency surgery. I hope your patient survives with no major defects. | ||

| Post# 37091 , Reply# 5 4/3/2008 at 18:55 (5,856 days old) by camelotshadow (Valley Village) | ||

|

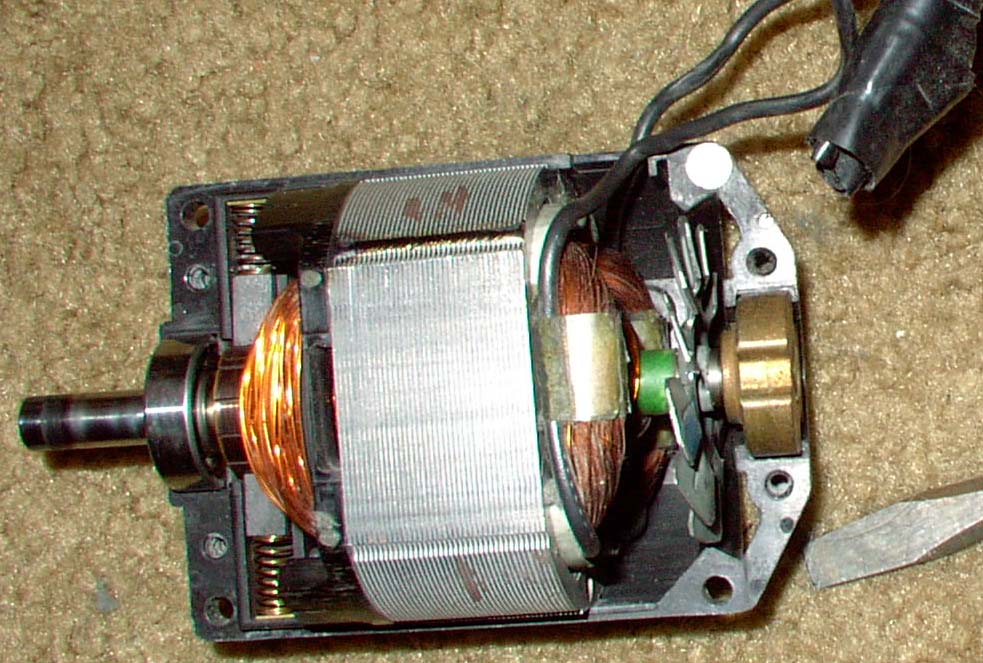

Hope I straighten a good position Tried to get them back to where I thought they would be best with what I had to work with not wanting to go to fan & break off a blade Actually the operation I thought went well

| ||

| Post# 37101 , Reply# 9 4/3/2008 at 20:37 (5,856 days old) by camelotshadow (Valley Village) | ||

|

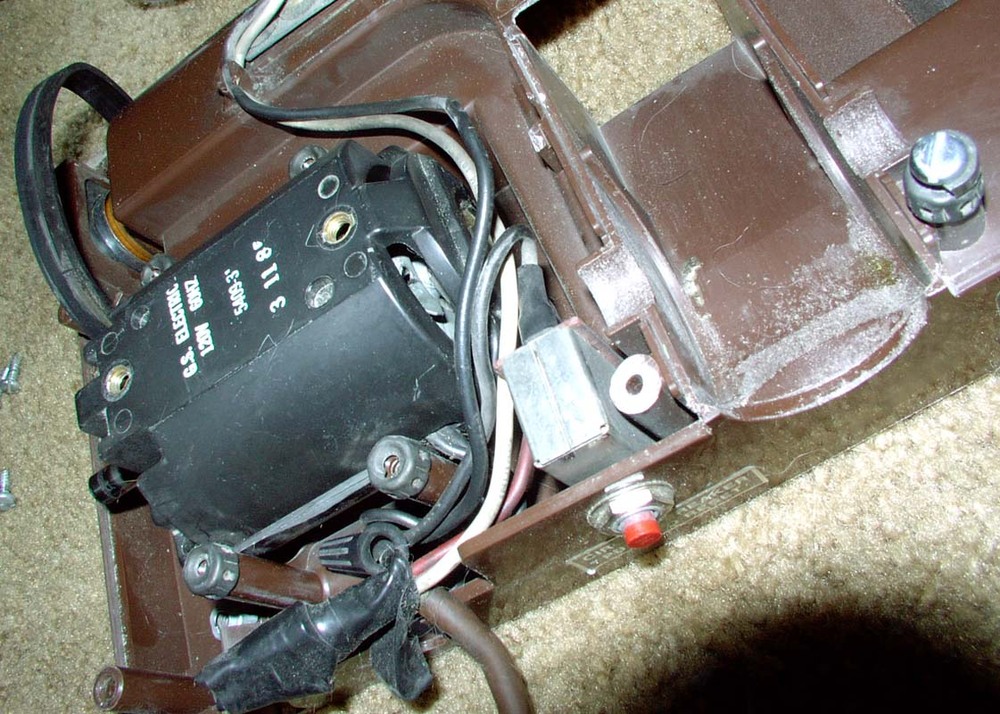

GS? Is that a brand? Hey, You're good Hoe did you know that?

| ||

| Post# 37144 , Reply# 16 4/4/2008 at 02:05 (5,855 days old) by beerad (Beautiful Vancouver BC) | ||

|

I have the samilar one I have the similar F/Q,,, and mine is 1978 it runs perfectly,, and the hinges are a bit flexable, and they work correctly. Change the little round filter inside the cone,,that is key for these queens to run good. That has been my expereince with all three of my F/Q...great vacs they are..

| ||

| Post# 37211 , Reply# 23 4/4/2008 at 23:15 (5,855 days old) by camelotshadow (Valley Village) | ||

|

balancing Anyone has a pic of the alignment of blades of a good fan? I had nothing to work from on this one had to reconstruct it from intuition... Think I angled them less than they should be OOH well its works LOL | ||

Post# 37225 , Reply# 27 4/5/2008 at 08:49 (5,854 days old) by arh1953  ( River Park, in Port St. Lucie, Florida) ( River Park, in Port St. Lucie, Florida) |

||

| ||

Comes to the Rescue!

Comes to the Rescue!