|

Thread Number: 23805

How do you unscrew a screw that wont budge |

[Down to Last] |  |

| Post# 266642 2/8/2014 at 07:35 (3,722 days old) by thekirbylover (Warrington, cheshire ) | ||

So I was trying to take a Hoover Junior U1012 apart for cleaning, however the screw at the rear of the motor wont come out the screwdriver just turns without actually catching onto the screw and when it does it will just slip if put under any pressure I have tried the rubber band trick and it still wont work, does anyone have any suggestions as I really want to get this Junior working again.

| ||

| Post# 266679 , Reply# 1 2/8/2014 at 12:36 (3,722 days old) by super-sweeper (KSSRC Refurbishment Center) | ||

|

... Be sure you're using the correct sized screw-driver, I've had a failure of screw in which the screws on a Hoover Kwik-Broom would not budge. Then I bought the correct sized driver and Eureka (Pun intended)! the screws came out with pressure and strength! WD-40 also works wonders on old, rusty, seized screws! | ||

Post# 266688 , Reply# 2 2/8/2014 at 13:04 (3,722 days old) by KirbyClassicIII  (Milwaukie, Oregon) (Milwaukie, Oregon) |

||

E-Z Out | ||

| Post# 266776 , Reply# 3 2/8/2014 at 18:01 (3,722 days old) by ornery (Northeast Ohio) | ||

If I'm Looking At The Right Screw(s) | ||

| Post# 266846 , Reply# 4 2/9/2014 at 08:31 (3,721 days old) by thekirbylover (Warrington, cheshire ) | ||

| ||

| Post# 266848 , Reply# 5 2/9/2014 at 09:19 (3,721 days old) by ornery (Northeast Ohio) | ||

Might Need Screw Extractor

Well, if you can't grind flats on the sides of the head, you could try drilling the head right off, then use "Vise Grips" to remove the remnant when you do get the motor separated from the body.

I've rarely had any luck with screw extractors, but I've heard the square style works OK. Never tried them myself, so good luck. CLICK HERE TO GO TO ornery's LINK

| ||

| Post# 266854 , Reply# 6 2/9/2014 at 09:56 (3,721 days old) by ornery (Northeast Ohio) | ||

Forgot About Drilling It Out

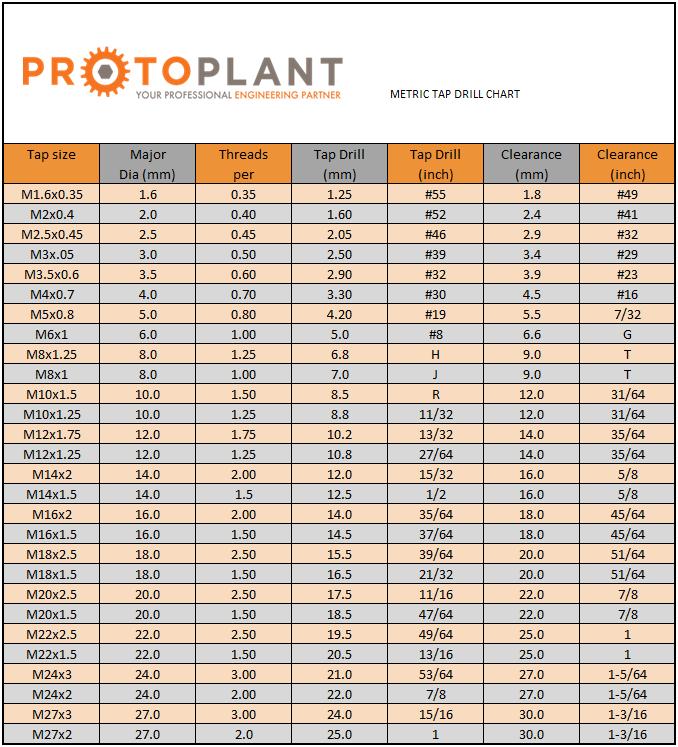

Oops, forgot to mention you may be able to drill it all the way out. If you can drill straight down the center, which is doable with a philips head screw. And, you can find the size of the screw, use the tap drill for that size. If you can get a left handed twist drill that would be the ultimate. For instance, if it's an M6x1 screw, you would use an M5 drill bit.

CLICK HERE TO GO TO ornery's LINK

| ||

| Post# 266890 , Reply# 7 2/9/2014 at 19:44 (3,721 days old) by Vacosaurus (Cleveland ohio) | ||

|

Use a hacksaw and cut a slot across the head and make it like a regular slotted screw and use a regular screwdriver. | ||

| Post# 266922 , Reply# 8 2/10/2014 at 03:56 (3,720 days old) by bnsd60m9200 (Akron OH) | ||

there are much easier and less damaging ways to get seized screws out. that will actually preserve said original screw (as many vac screws were specialty and NLA now)without boogering the threads or screw head up.

i use three methods depending on the severity of rust seizing the screw 1. slighty oversized screwdriver and hammer. pounding a hammer on the end of the screw driver gives a jolting force that can jar a screw loose enough to give you torque with a screwdriver to get said screw loose 2. angled screw driver and hammer. these angled screwdrivers usually have screw heads on either end and are shaped like a hand crank. these drivers are meant for alot of torque just for this kind of problem. this usually gets most screws unstuck for me. 3. if neither of those methods work, i use PB penatrating catalyst (an industrial solvent you can get at home depot) to work on the rust holding the screw in, then use steps one or two after. 4. if none of those methods work, try step 3, but instead of screw drivers, a high torque drill like a makita or dewalt cordless with a screw bit on the wend. preferably and impact drill. 95% of the time tho, methods 1-3 will get a screw unstuck. there is no need to destroy a screw to get it unseized, especially in our hobby where replacement screws for certain vacs cant be substituted with generic screws from ace, home depot or lowe's. | ||

| Post# 266926 , Reply# 9 2/10/2014 at 05:09 (3,720 days old) by ornery (Northeast Ohio) | ||

Hey, That's All True...

...but, it sounds like the screw is already fubarred. That's a good point, to head off the problem before it starts. Use the right size screwdriver in the first place, and make sure its tip is in good condition. Heck, make sure you're using a good screwdriver in the first place. If you bought a set of eight screwdrivers for five dollars at the the local grocery store, chances are they're not made of the finest, tempered steel.

Also it's a good idea to see if the screw head is free of debris. Blow it out with compressed air if need be. If the screwdriver doesn't seat in the bottom, you're off to a bad start, and possibly a rounded out head. Lastly, it helps to bear down hard from the start, and make sure it doesn't start to slip in the first place. Once it starts to slip, it only gets worse. But, that's all moot for thekirbylover. Hindsight is 20/20... | ||

Comes to the Rescue!

Comes to the Rescue!