|

Thread Number: 11919

New project of the day - Riccar 1500S. |

[Down to Last] |  |

| Post# 127801 , Reply# 1 3/18/2011 at 22:31 (4,780 days old) by gmerkt (Edmonds WA) | ||

|

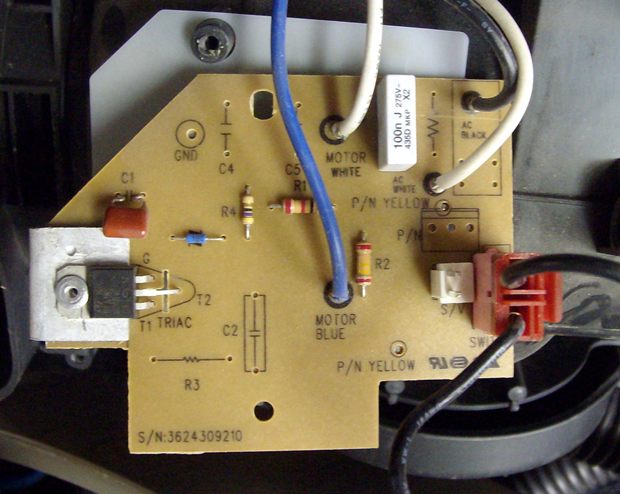

Riccar 1500S electronics This is a closer picture of the top of the circuit board in the Riccar. The triac with the bad joint is the black square on the left in the picture.

| ||

| Post# 127802 , Reply# 2 3/18/2011 at 22:32 (4,780 days old) by gmerkt (Edmonds WA) | ||

|

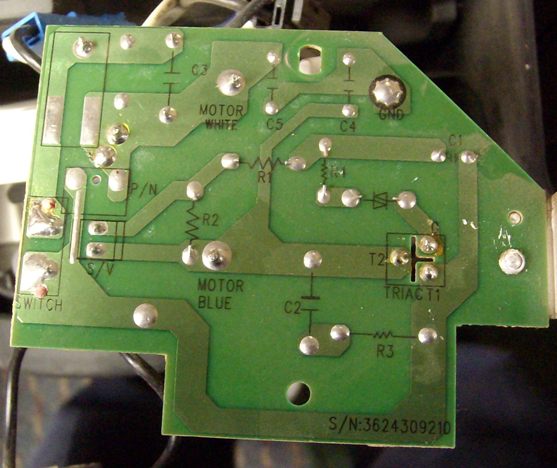

Riccar 1500S electronics This picture is of the back of the board; the bad joint was T2 which I resoldered.

| ||

| Post# 127809 , Reply# 3 3/18/2011 at 23:23 (4,780 days old) by aeoliandave (Stratford Ontario Canada) | ||

| ||

| Post# 128227 , Reply# 5 3/22/2011 at 20:32 (4,776 days old) by vac_whisperer () | ||

|

Dave, That comic was in my local Gazette the same day you posted it! VW | ||

Comes to the Rescue!

Comes to the Rescue!