|

Thread Number: 34065

/ Tag: 50s/60s/70s Vacuum Cleaners

Flour UNDER the Carpet Test For Hoover U4007 |

[Down to Last] |  |

| Post# 369191 3/25/2017 at 16:40 (2,581 days old) by wyaple (Pickerington, OH) | ||

I bought a new 5'x7' Mohawk medium pile carpet for vacuum tests in my basement recently. I wanted to see what vacuums had enough power to pull flour up through the carpet into the dust bag.

The test was completed with only 2 complete strokes (2 forward/2 backward) at medium speed right through the middle of the flour. I think this qualifies as maybe 95%-99% total pickup? This Hoover Convertible U4007 was quite the winner with 107 CFM at the nozzle and an airflow density of about 4.6 CFM per square inch. AND all this cleaning power comes from a motor only requiring 4.1 Amps @ 120 Volts = 492 Watts. Enjoy! Oh, and I will be publishing more of these tests as time permits. Bill | ||

| Post# 369391 , Reply# 2 3/28/2017 at 09:39 (2,579 days old) by kirbyvertibles (Independence, KS) | ||

Never underestimate the vacuum with low power!!! I remember at last years convention in the cleaning competition there were 2 power vacuums (I forget now what they were) and someone asked if they could use my little 1971 RCA Whirlpool 2,000 stick vac looking vacuum. I said sure but that's kind of unfair to the poor little Whirlpool. Everyone thought awe the poor little guy......... Well I'll be damned if I didn't bring home a first place ribbon as it beat the others.

| ||

| Post# 369667 , Reply# 4 3/31/2017 at 14:38 (2,576 days old) by dysonman1 (the county) | ||

Tacony Manufacturing

Tests brand new vacuums (the ones they make as well as competitors) using a very scientific method.

A mechanical arm to "push" the vacuums is used, so the human variable is eliminated. A brand new piece of test carpet is cut to fit a platform with a standard pad attached. A standard mixture of test dirt (looks like sand and talc to me) is measured, weighed, and applied to the carpet, then a heavy roller is used to 'grind' it in. The carpet containing the 'dirt' is weighed. The carpet is laid on top of the pad, and the vacuum being tested goes to work for a standard number of test 'strokes' (8 I believe). The carpet is then reweighed - the difference is the percentage of dirt 'picked up'. The testing lab is also used for two other tests - durability (life of the motor) and carpet wear tests. Vacuums run constantly, with the mechanical arm pushing the machine, until the motors die. The number of minutes (hours) is calculated to determine motor life. Carpets are also weighed at the beginning and end of the life tests - any loss of carpet nap is determined by weighing, as well as an observation test to see (by a human) any negative effects to the carpet. Years ago, the old VCCC went to the Kirby Company. We were in the testing labs, and the engineers gave us a piece of test carpet, which the old VCCC used for the cleaning contests. I've had nothing to do with the VCCC for more than a decade, so I have no idea if the same carpet is being used today for their tests. However, at the time, the Kirby Company told us that ALL manufacturers use the same brand and type of carpet for their wear and cleaning tests. | ||

| Post# 369676 , Reply# 5 3/31/2017 at 15:46 (2,575 days old) by wyaple (Pickerington, OH) | ||

Warren,

It doesn't take much to perform tests on these machines. Even if my measurements are off by a whopping 1%, you and I know that's not very statistically significant.

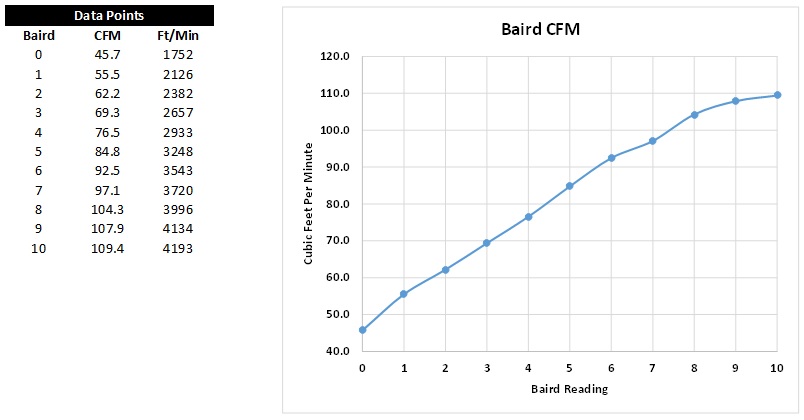

For "quick and dirty" airflow tests, use a Baird meter (right now Tom G. is cringing). My airflow chart for it is posted here so you'll know what an "8" actually means. For my precision tests, grab yourself a GM8901 anemometer for about $25 from eBay. Get a more expensive meter if you desire, but this cheapie can register airflow up to 260 CFM (10,000 ft/min) in repeatable increments of less than 0.5 CFM (about 20 ft/min). If all you desire to test is small airflow drops from a hose, the Baird meter will reliably tell you when about 3-4 CFM is lost by reading about one-half a number lower (at least in the zero to 8 range). I would imagine that a 3-4 CFM loss is probably good enough resolution for most people. Of course being an Engineer, follow the exact same initial conditions when testing. Hose stretched out the same way, same line voltage, and bag and/or cyclone cleanliness, etc. For measuring line voltage and/or current, nothing fancy is necessary either. I have a single piece of bench gear that originally costs well over $2000 and can read out to 8 digits of accuracy. A complete waste as a $13 power consumption meter is plenty fine. If you want an airflow box, you'll have to build your own, but they are easy to construct. I made mine essentially for free out of cardboard (sealed it of course) and can reliably measure from about 2 CFM to 150 CFM from nozzle heads, which is good enough for now I suppose. Feel free to email me for more info... Bill CLICK HERE TO GO TO wyaple's LINK on eBay

| ||

| Post# 369915 , Reply# 6 4/3/2017 at 15:27 (2,572 days old) by Warren_L (Georgia, USA) | ||

|

How did you arrive at the data points of the Baird Meter? What calibration tool did you use? | ||

| Post# 369927 , Reply# 7 4/3/2017 at 20:09 (2,572 days old) by wyaple (Pickerington, OH) | ||

Warren, | ||

Comes to the Rescue!

Comes to the Rescue!