|

Thread Number: 12704

Electrolux Model B21 And B27 Shampooer |

[Down to Last] |  |

| Post# 135806 , Reply# 2 5/8/2011 at 20:46 (4,735 days old) by steve (Makawao) | ||

|

Bumper removal Thanks for the info. How do I get the rubber bumper off; it seems to be as tight as a bicycle tire :-) | ||

| Post# 136675 , Reply# 4 5/15/2011 at 15:39 (4,728 days old) by steve (Makawao) | ||

|

removing gears Hi Vernon Finally got the bumper off. But I don't see a way to get the front gears off; it seems that a white plastic ring hold the spindle and don't see a way of removing them (got the small rngs off the groove on the spindles). | ||

| Post# 136685 , Reply# 5 5/15/2011 at 18:22 (4,728 days old) by aeoliandave (Stratford Ontario Canada) | ||

Steve, removing any one of the gears is not quickly done but it is easily done. I tore down mine a few years back because two of the nylon gears were shredded and I happened to find a derilict polisher in the trash with good gears. So it was worth the effort.

The spindles are press-fitted into pierced metal discs and the nylon tooth gear rings are are molded around the disc, essentially a one-piece unit that cannot be repaired when the teeth have shattered and sheared off. If you don't have replacement gears standing by there's no point in going this far. The gear spindles pass through bronze bearings in the base plate (as I call it) and are held in place with circlip C washers. the three spindle axles are shrouded in capped wells packed with shredded felt holding grease/oil. DO NOT discard this packing material! Remove the c-clip and the gears pop out. But first you have to remove the cordwinder assembly and motor cap to access the wells after removing the caps and packing. In reverse order then, we begin with the spindle wells exposed after replacing gears and C-clips.

| ||

| Post# 136687 , Reply# 6 5/15/2011 at 18:26 (4,728 days old) by aeoliandave (Stratford Ontario Canada) | ||

| ||

| Post# 136688 , Reply# 7 5/15/2011 at 18:32 (4,728 days old) by aeoliandave (Stratford Ontario Canada) | ||

| ||

| Post# 136689 , Reply# 8 5/15/2011 at 18:43 (4,728 days old) by aeoliandave (Stratford Ontario Canada) | ||

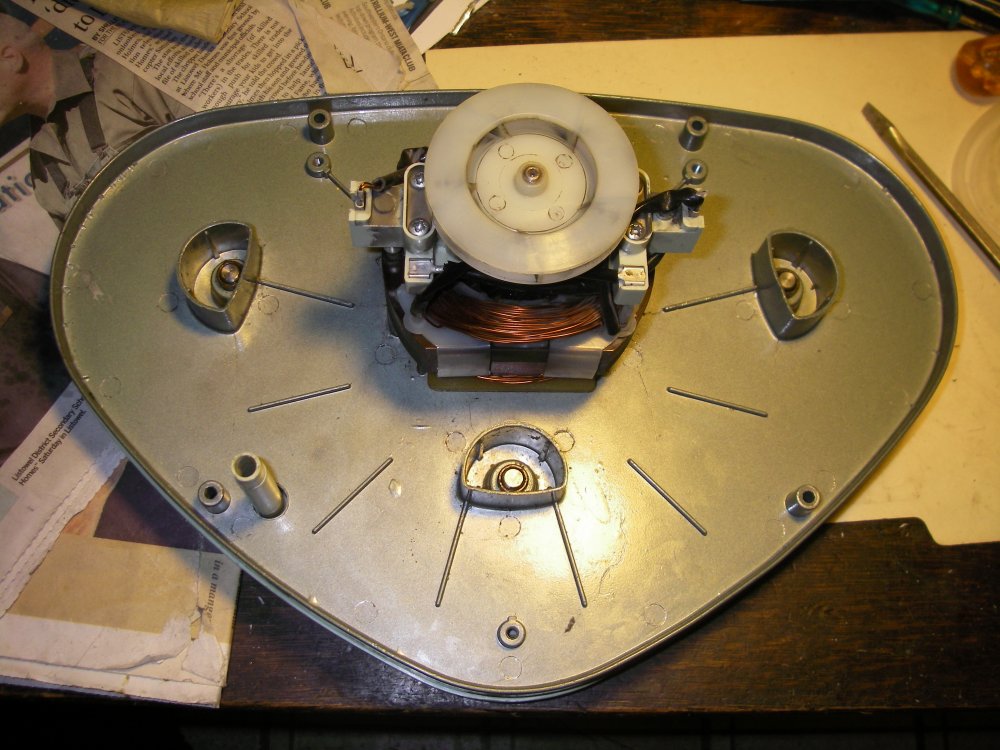

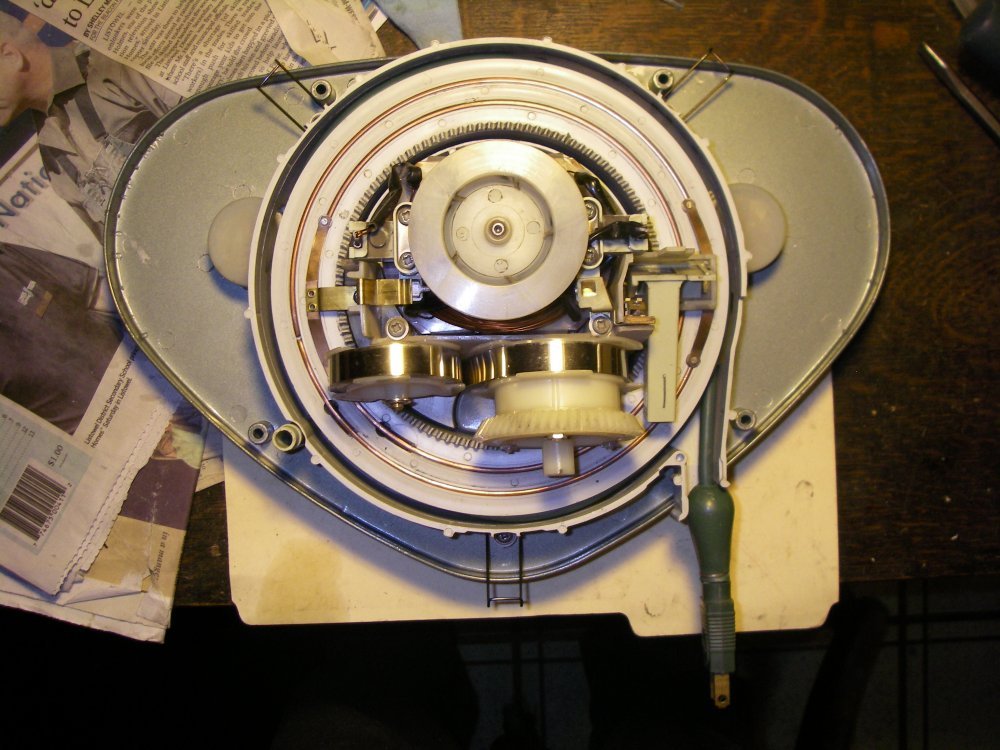

The top cap of the cordwinder is not screwed on - it is a loose fit held in place with three hinged spring clips attached to the base casting. The assembly layers are clamped tightly in place when the outer shell is screwed on at final assembly.

Here's what's underneath. Note that electrical connections are all flat blades slipping into mating sockets so no re-wiring is required. You really don't want to disturb the winder workings and a warning - do not hold the cordwinder assembly upside down or tilted when removing/replacing as the various gears and drums can fall out. The top cap holds the gears in close contact mesh. Worse still, if the large angled gear lifts out of the cord reel gear track the tempered steel flatspring will unsproing violently! Then the spring will have to be re-wound onto the drum it came off. Not a pleasant task...involving both hands, your chin and possibly your big toe all in constant contact...

This post was last edited 05/15/2011 at 19:15 | ||

| Post# 136692 , Reply# 9 5/15/2011 at 18:55 (4,728 days old) by aeoliandave (Stratford Ontario Canada) | ||

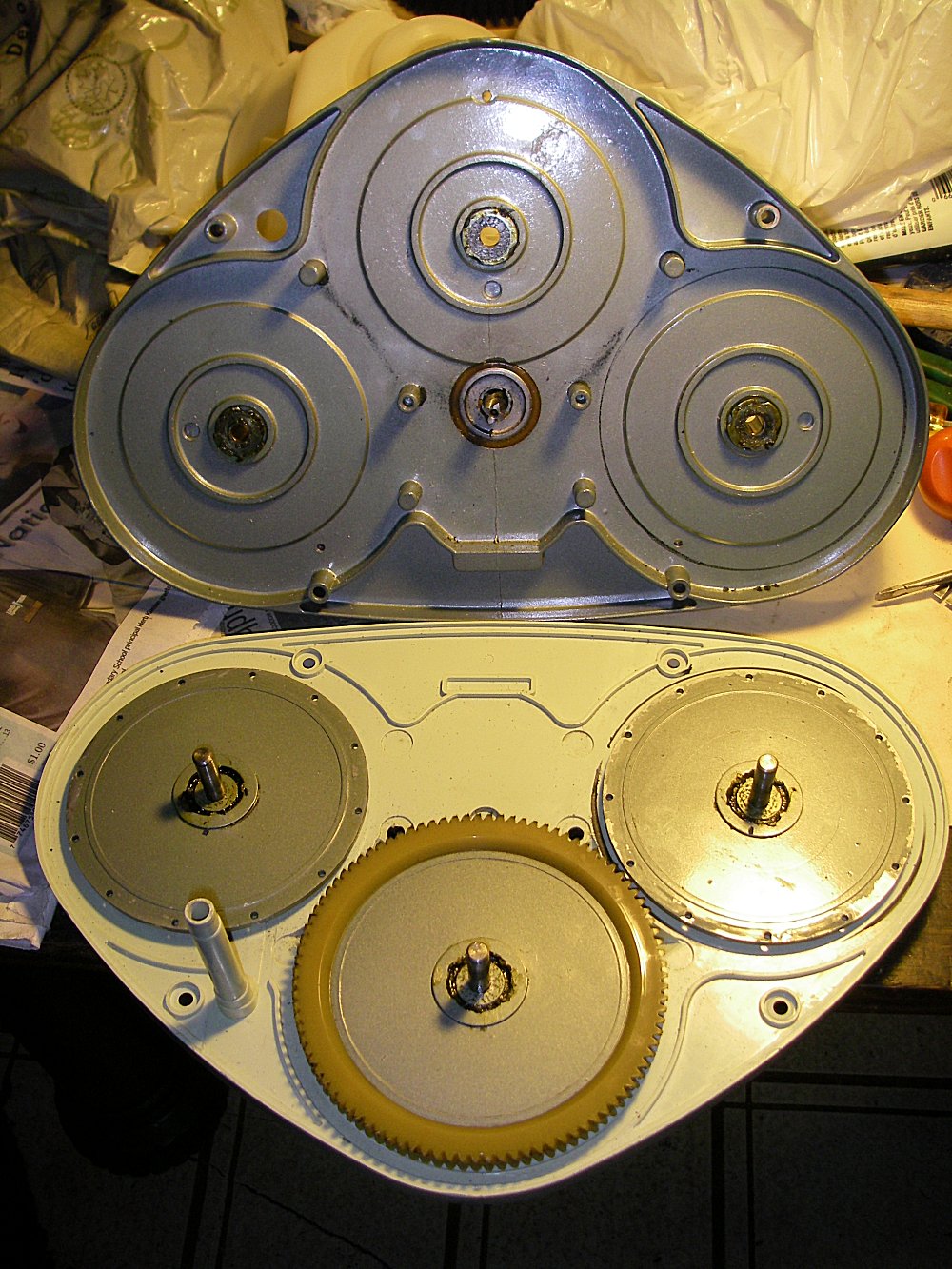

here's the underside showing gears that have crumbled gears cleaned off and it shows the pierced edge of the central disc. The nylon gears are molded in place like a car tire and once shattered cannot be replaced except by an entire assembly from a donor machine, or two. The three gears & spindle axles are interchangeable and as noted previously it seems always that the outer gears are the first to shatter.

This post was last edited 05/15/2011 at 19:29 | ||

| Post# 136693 , Reply# 10 5/15/2011 at 19:00 (4,728 days old) by aeoliandave (Stratford Ontario Canada) | ||

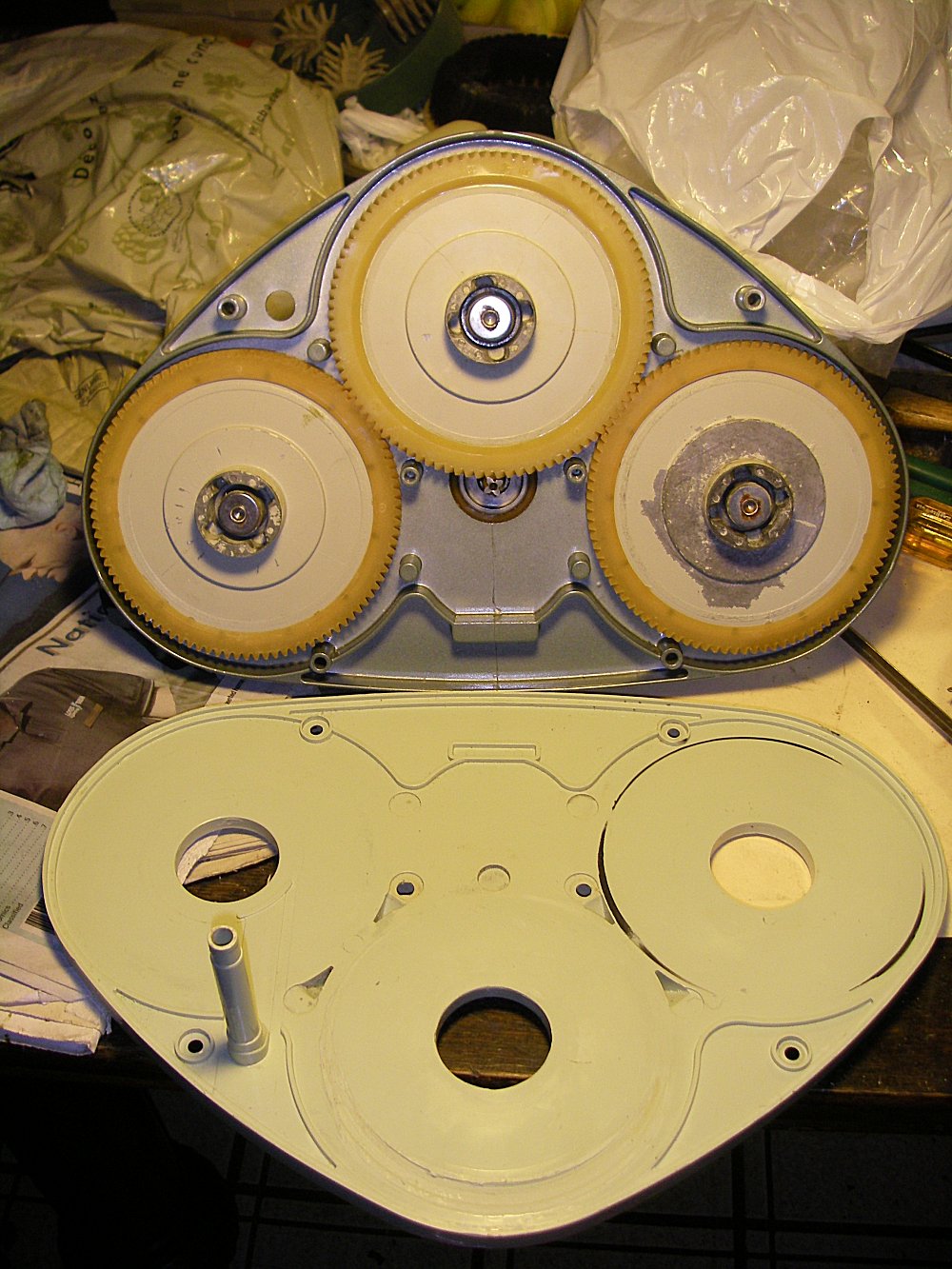

Gears replaced from donor machine; that's why they are cream coloured.

Perhaps the later machines had better shatter-resistant gear material? machine ready for re-assembly.

This post was last edited 05/15/2011 at 19:31 | ||

| Post# 136694 , Reply# 11 5/15/2011 at 19:19 (4,728 days old) by aeoliandave (Stratford Ontario Canada) | ||

| ||

| Post# 136695 , Reply# 12 5/15/2011 at 19:24 (4,728 days old) by aeoliandave (Stratford Ontario Canada) | ||

| ||

Comes to the Rescue!

Comes to the Rescue!